PLC Repair & Machine Reconditioning

Our Services

Need Assistance?

Contact our team of experts to discuss your PLC repair and machine reconditioning requirements.

Contact UsPLC Repair & Machine Reconditioning Services

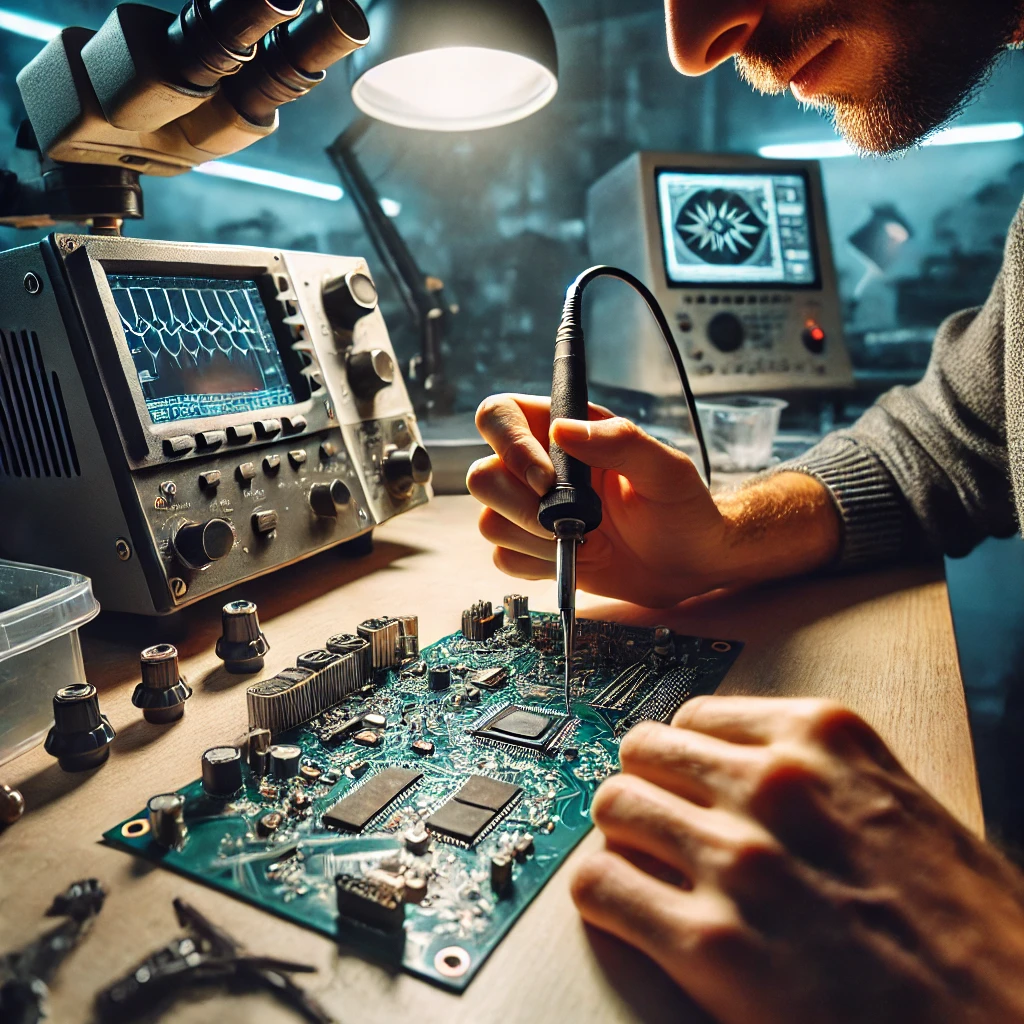

Tag Automation offers comprehensive PLC repair and machine reconditioning services to extend the life of your automation equipment and minimize downtime. Our team of experienced technicians specializes in diagnosing and repairing PLCs, HMIs, drives, and other automation components from all major manufacturers.

Our PLC Repair Services Include:

PLC module repair and replacement

I/O card troubleshooting and repair

Power supply repair and replacement

Communication module repair

Memory backup and restoration

Firmware updates and upgrades

Emergency repair services

Preventive maintenance programs

Machine Reconditioning Services:

Complete machine assessment and evaluation

Control system upgrades and modernization

Mechanical component repair and replacement

Electrical system rewiring and upgrades

Software updates and optimization

Safety system upgrades to meet current standards

Performance testing and validation

Documentation and training

Brands We Support:

- Siemens: S7-200, S7-300, S7-400, S7-1200, S7-1500 series

- Allen Bradley: PLC-5, SLC 500, ControlLogix, CompactLogix series

- Mitsubishi: FX series, Q series, L series

- Omron: CJ, CP, CS series

- Schneider Electric: Modicon, Telemecanique, M340, M580 series

- ABB: AC500, AC800 series

- Delta: DVP, AH series

Benefits of Our Repair & Reconditioning Services:

- Cost-effective alternative to new equipment purchase

- Reduced downtime and production losses

- Extended equipment life

- Improved reliability and performance

- Warranty on all repair services

- 24/7 emergency repair services available

- Comprehensive documentation and support

Our Repair Process:

- Diagnosis: We thoroughly diagnose the issue to identify the root cause of the problem.

- Repair Proposal: We provide a detailed repair proposal including cost and timeline.

- Repair: Our technicians repair or replace the faulty components using genuine parts.

- Testing: We perform comprehensive testing to ensure the equipment functions correctly.

- Delivery: We deliver the repaired equipment with a warranty on our workmanship.

- Follow-up: We provide follow-up support to ensure continued proper operation.

Whether you need emergency repair services or are looking to extend the life of your aging equipment through reconditioning, our team of experts is ready to help. Contact us today to discuss your PLC repair and machine reconditioning requirements.